Scientists Find Way to Turn Waste Plastics into Jet Fuel-Range Hydrocarbons

Jun 4, 2019 by News Staff / Source

In experiments described in the journal Applied Energy, a team of researchers from China and the U.S. melted plastic waste at high temperature with activated carbon to produce transportation jet fuel.

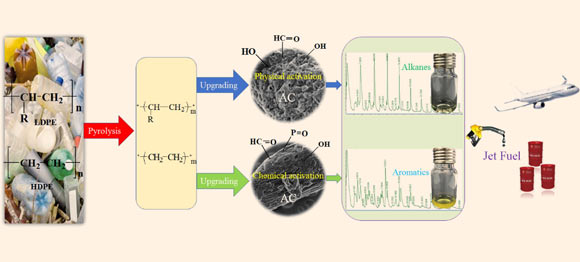

Zhang et al studied catalytic pyrolysis of waste plastics over activated carbon catalyst. Image credit: Zhang et al, doi: 10.1016/j.apenergy.2019.113337.

With the increasing amount of waste plastics being used domestically and industrially, the disposition of those being not reusable is a challenging task.

According to the Environmental Protection Agency, landfills in the U.S. received 26 million tons of plastic in 2015.

“Waste plastic is a huge problem worldwide. This is a very good, and relatively simple, way to recycle these plastics,” said lead author Dr. Hanwu Lei, a scientist at Washington State University.

In the experiments, Dr. Lei and colleagues tested low-density polyethylene and mixed a variety of waste plastic products, like water bottles, milk bottles, and plastic bags, and ground them down to around 3 mm.

The plastic granules were then placed on top of activated carbon catalyst in a tube reactor at a high temperature, ranging from 806 to 1,060 degrees Fahrenheit (430-571 degrees Celsius).

“Plastic is hard to break down. You have to add a catalyst to help break the chemical bonds,” Dr. Lei said.

“There is a lot of hydrogen in plastics, which is a key component in fuel.”

Once the carbon catalyst has done its work, it can be separated out and re-used on the next batch of waste plastic conversion. The catalyst can also be regenerated after losing its activity.

After testing several different catalysts at different temperatures, the best result the team had produced a mixture of 85% jet fuel and 15% diesel fuel.

“We can recover almost 100% of the energy from the plastic we tested,” Dr. Lei said.

“The fuel is very good quality, and the byproduct gasses produced are high quality and useful as well.”

“The method for this process is easily scalable. It could work at a large facility or even on farms, where farmers could turn plastic waste into diesel,” he added.

“You have to separate the resulting product to get jet fuel. If you don’t separate it, then it’s all diesel fuel.”

_____

Yayun Zhang et al. 2019. Jet fuel production from waste plastics via catalytic pyrolysis with activated carbons. Applied Energy 251: 113337; doi: 10.1016/j.apenergy.2019.113337

Thanks to: http://www.sci-news.com

Jun 4, 2019 by News Staff / Source

In experiments described in the journal Applied Energy, a team of researchers from China and the U.S. melted plastic waste at high temperature with activated carbon to produce transportation jet fuel.

Zhang et al studied catalytic pyrolysis of waste plastics over activated carbon catalyst. Image credit: Zhang et al, doi: 10.1016/j.apenergy.2019.113337.

With the increasing amount of waste plastics being used domestically and industrially, the disposition of those being not reusable is a challenging task.

According to the Environmental Protection Agency, landfills in the U.S. received 26 million tons of plastic in 2015.

“Waste plastic is a huge problem worldwide. This is a very good, and relatively simple, way to recycle these plastics,” said lead author Dr. Hanwu Lei, a scientist at Washington State University.

In the experiments, Dr. Lei and colleagues tested low-density polyethylene and mixed a variety of waste plastic products, like water bottles, milk bottles, and plastic bags, and ground them down to around 3 mm.

The plastic granules were then placed on top of activated carbon catalyst in a tube reactor at a high temperature, ranging from 806 to 1,060 degrees Fahrenheit (430-571 degrees Celsius).

“Plastic is hard to break down. You have to add a catalyst to help break the chemical bonds,” Dr. Lei said.

“There is a lot of hydrogen in plastics, which is a key component in fuel.”

Once the carbon catalyst has done its work, it can be separated out and re-used on the next batch of waste plastic conversion. The catalyst can also be regenerated after losing its activity.

After testing several different catalysts at different temperatures, the best result the team had produced a mixture of 85% jet fuel and 15% diesel fuel.

“We can recover almost 100% of the energy from the plastic we tested,” Dr. Lei said.

“The fuel is very good quality, and the byproduct gasses produced are high quality and useful as well.”

“The method for this process is easily scalable. It could work at a large facility or even on farms, where farmers could turn plastic waste into diesel,” he added.

“You have to separate the resulting product to get jet fuel. If you don’t separate it, then it’s all diesel fuel.”

_____

Yayun Zhang et al. 2019. Jet fuel production from waste plastics via catalytic pyrolysis with activated carbons. Applied Energy 251: 113337; doi: 10.1016/j.apenergy.2019.113337

Thanks to: http://www.sci-news.com

Sat Mar 23, 2024 11:33 pm by globalturbo

Sat Mar 23, 2024 11:33 pm by globalturbo