Builders Are Using Hemp Instead of Concrete and It Could Save the Environment

By John Vibes

By John Vibes

It’s hard to imagine that cement could possibly be replaced by any other material for major construction projects, but the industry is starting to look at alternatives for a variety of different environmental and economic reasons.

According to Bloomberg, cement manufacturers are responsible for roughly 7% of annual global carbon dioxide emissions. Furthermore, the massive demand for cement has created a global shortage of sand, which could have a disastrous impact on both the environment and the economy.

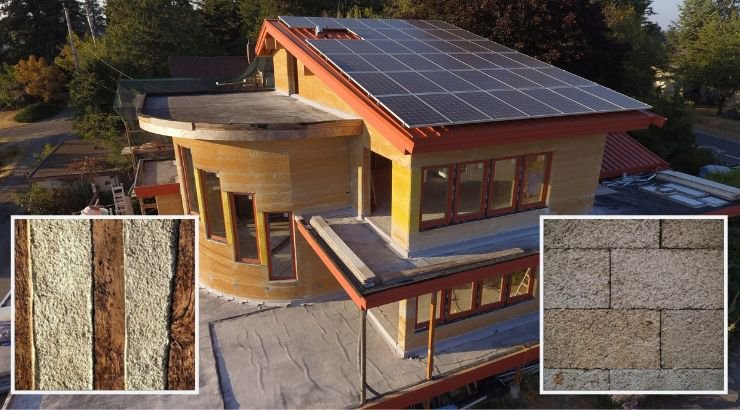

Surprisingly, hemp-based concretes are among the most promising and environmentally sustainable alternatives to conventional concrete. This is not just a theoretical idea or prediction, but something that builders are already implementing in their architecture.

64-year-old Mac Radford, owner of JustBioFiber Structural Solutions, one of the leading manufacturers of hemp-concrete, says that demand for the material has increased so much in recent years that he is having a hard time keeping up with the demand, and once his recent expansion is completed, he estimates that his company will be producing enough hemp brick to build roughly 2,000 homes per year.

Radford told Bloomberg that his company is already making a profit, and with a new $28 million investment, they hope to continue their expansion even further.

Hempcrete was initially developed in France over 30 years ago. However, the use of hemp in construction materials dates back as far as ancient Rome when it was mixed into the mortar that was used to build bridges. It was not until recently that modern builders actually started taking this material seriously and began considering it for large-scale projects.

In addition to being better for the environment, hempcrete is also more resistant to fire, regulates temperature better and offers better ventilation than conventional concrete.

According to Quentin Pichon, the founder of CAN-Ingenieurs Architectes, a company specializing in hempcrete, the material is becoming increasingly common and was even used in the construction of a seven-story municipal building, although he did not reveal the specific location.

As previously reported by the Mind Unleashed, Dutch company Dun Agro put a hemp home on display in late 2018. Dun Agro hempcrete is made from hemp fibers, water and glue. After it is pressed together in a mold to make prefab sections, the mixture dries over a period of three months before the sections are assembled to create an entire home.

More sustainable alternatives in construction are certainly needed as they are in nearly every industry. Beyond the concerns of greenhouse gas emissions, there is simply not enough sand to sustain the increasing demand for conventional concrete. This poses yet another environmental crisis, as the specific type of sand needed for concrete is often harvested from riverbeds, which destroys ecosystems and threatens the biodiversity of plants, fish and animals.

It isn’t something that people think about often, but sand is the second most used natural resource in the world, surpassed only by water. This high demand often creates an incentive for criminal cartels to fight over resource-rich territories in the developing world, disrupting the local ecosystem and terrorizing civilians who attempt to get in their way.

If the construction industry were to fully adopt a renewable alternative like hemp, it could radically improve some of these social, environmental and economic concerns.

By John Vibes | Creative Commons | TheMindUnleashed.com

MORE HERE: https://www.naturalblaze.com/2019/09/builders-are-using-hemp-instead-of-concrete-and-it-could-save-the-environment.html?utm_source=Natural+Blaze+Subscribers&utm_medium=email&utm_campaign=b967824608-RSS_EMAIL_CAMPAIGN&utm_term=0_b73c66b129-b967824608-388109773

Thanks to: https://www.naturalblaze.com

By John Vibes

By John VibesIt’s hard to imagine that cement could possibly be replaced by any other material for major construction projects, but the industry is starting to look at alternatives for a variety of different environmental and economic reasons.

According to Bloomberg, cement manufacturers are responsible for roughly 7% of annual global carbon dioxide emissions. Furthermore, the massive demand for cement has created a global shortage of sand, which could have a disastrous impact on both the environment and the economy.

Surprisingly, hemp-based concretes are among the most promising and environmentally sustainable alternatives to conventional concrete. This is not just a theoretical idea or prediction, but something that builders are already implementing in their architecture.

64-year-old Mac Radford, owner of JustBioFiber Structural Solutions, one of the leading manufacturers of hemp-concrete, says that demand for the material has increased so much in recent years that he is having a hard time keeping up with the demand, and once his recent expansion is completed, he estimates that his company will be producing enough hemp brick to build roughly 2,000 homes per year.

Radford told Bloomberg that his company is already making a profit, and with a new $28 million investment, they hope to continue their expansion even further.

Hempcrete was initially developed in France over 30 years ago. However, the use of hemp in construction materials dates back as far as ancient Rome when it was mixed into the mortar that was used to build bridges. It was not until recently that modern builders actually started taking this material seriously and began considering it for large-scale projects.

In addition to being better for the environment, hempcrete is also more resistant to fire, regulates temperature better and offers better ventilation than conventional concrete.

According to Quentin Pichon, the founder of CAN-Ingenieurs Architectes, a company specializing in hempcrete, the material is becoming increasingly common and was even used in the construction of a seven-story municipal building, although he did not reveal the specific location.

As previously reported by the Mind Unleashed, Dutch company Dun Agro put a hemp home on display in late 2018. Dun Agro hempcrete is made from hemp fibers, water and glue. After it is pressed together in a mold to make prefab sections, the mixture dries over a period of three months before the sections are assembled to create an entire home.

More sustainable alternatives in construction are certainly needed as they are in nearly every industry. Beyond the concerns of greenhouse gas emissions, there is simply not enough sand to sustain the increasing demand for conventional concrete. This poses yet another environmental crisis, as the specific type of sand needed for concrete is often harvested from riverbeds, which destroys ecosystems and threatens the biodiversity of plants, fish and animals.

It isn’t something that people think about often, but sand is the second most used natural resource in the world, surpassed only by water. This high demand often creates an incentive for criminal cartels to fight over resource-rich territories in the developing world, disrupting the local ecosystem and terrorizing civilians who attempt to get in their way.

If the construction industry were to fully adopt a renewable alternative like hemp, it could radically improve some of these social, environmental and economic concerns.

By John Vibes | Creative Commons | TheMindUnleashed.com

MORE HERE: https://www.naturalblaze.com/2019/09/builders-are-using-hemp-instead-of-concrete-and-it-could-save-the-environment.html?utm_source=Natural+Blaze+Subscribers&utm_medium=email&utm_campaign=b967824608-RSS_EMAIL_CAMPAIGN&utm_term=0_b73c66b129-b967824608-388109773

Thanks to: https://www.naturalblaze.com

Sat Mar 23, 2024 11:33 pm by globalturbo

Sat Mar 23, 2024 11:33 pm by globalturbo