Newly-Developed ‘Acoustic Fabric’ Converts Sounds into Electrical Signals

Mar 18, 2022 by News Staff / Sourc

Fabrics, by virtue of their composition and structure, have traditionally been used as acoustic absorbers. Inspired by the auditory system, a team of engineers from MIT and elsewhere has created a fabric that operates as a sensitive audible microphone while retaining the traditional qualities of fabrics, such as machine washability and draping.

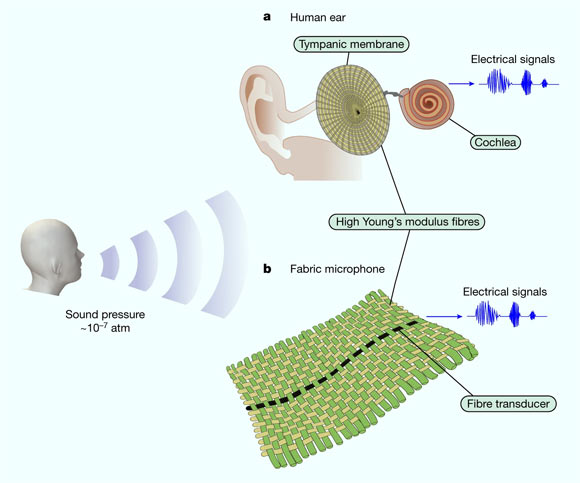

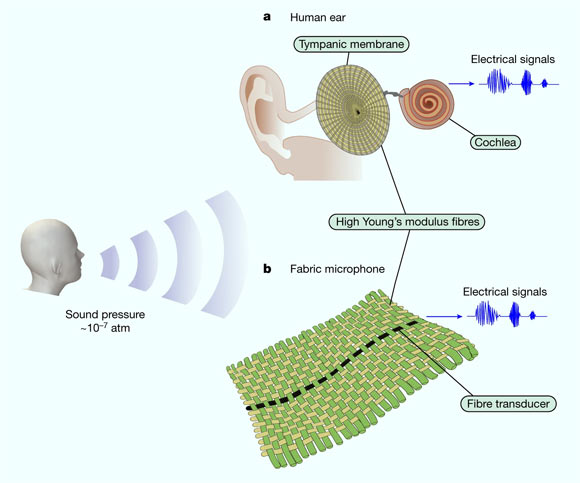

Yan et al. designed an acoustic fabric, woven with a fiber that is designed from a piezoelectric material that produces an electrical signal when bent or mechanically deformed: (a) the tympanic membrane is a four-layer construct composed of circumferentially and radially oriented high-modulus collagen fibers, which are key for sound conduction; the tympanic membrane motion is ultimately transmitted to the cochlea through the ossicular chain, wherein short cilia fibers convert pressure waves into electrical signals (ionic), which are picked up by the nervous system; (b) in the acoustic fabric, high-modulus Twaron yarns and cotton yarns are oriented at right angles, mimicking the construction of the tympanic membrane; this construction converts faint audible frequency sound pressure waves into low-order mechanical vibration modes; within that same medium, a single strand of piezoelectric elastomeric fiber transducer is woven, leading to a synergistically coupled fabric, where sound transduction is a collective effect; this results in a fabric capable of operating as a sensitive microphone that detects weak sound signals (for example, human speech) as low as 10-7 atm. Image credit: Yan et al., doi: 10.1038/s41586-022-04476-9.

The ubiquity of fabrics, together with recent breakthroughs in fiber technology, enable us to challenge traditional uses of fabrics to encompass new and potentially useful roles.

Fabrics have recently been shown to store energy, communicate, heat, cool, display and even store and process digital information.

Motivated by the extent of fabric usage, its unparalleled proximity to the human body, and the importance of acoustic signals, MIT researcher Wei Yan and colleagues set out to investigate whether fabrics could serve as efficient sound collectors to detect and process even faint audible signals.

The consequences of such a transformation in fabric use would be far-reaching — enabling fabrics to mediate acoustic communications, pick up acoustic health indicators from the body, and increase situational acoustic awareness.

“We sought to create a fabric ‘ear’ that would be soft, durable, comfortable, and able to detect sound,” the scientists said.

“Our research led to two important discoveries: such a fabric would have to incorporate stiff, or high-modulus, fibers to effectively convert sound waves into vibrations.”

“And, we would have to design a fiber that could bend with the fabric and produce an electrical output in the process.”

“With these guidelines in mind, we developed a layered block of materials called a preform, made from a piezoelectric layer as well as ingredients to enhance the material’s vibrations in response to sound waves.”

“The resulting preform, about the size of a thick marker, was then heated and pulled like taffy into thin, 40-m- (131-foot) long fibers.”

The authors tested the fiber’s sensitivity to sound by attaching it to a suspended sheet of mylar.

They used a laser to measure the vibration of the sheet in response to sound played through a nearby speaker.

The sound varied in decibel between a quiet library and heavy road traffic. In response, the fiber vibrated and generated an electric current proportional to the sound played.

“This shows that the performance of the fiber on the membrane is comparable to a handheld microphone,” said Dr. Grace Noel, also from MIT.

The researchers wove the fiber with conventional yarns to produce panels of drapable, machine-washable fabric.

They then tested the fabric’s sensitivity to directional sound by clapping their hands while standing at various angles to the shirt.

“The fabric was able to detect the angle of the sound to within 1 degree at a distance of 3 m (10 feet) away,” Dr. Noel said.

The team also stitched a single fiber to a shirt’s inner lining, just over the chest region, and found it accurately detected the heartbeat of a healthy volunteer, along with subtle variations in the heart’s S1 and S2, or lub-dub features.

In addition to monitoring one’s own heartbeat, the authors see possibilities for incorporating the acoustic fabric into maternity wear to help monitor a baby’s fetal heartbeat.

Finally, they reversed the fiber’s function to serve not as a sound-detector but as a speaker.

They recorded a string of spoken words and fed the recording to the fiber in the form of an applied voltage.

The fiber converted the electrical signals to audible vibrations, which a second fiber was able to detect.

In addition to wearable hearing aids, clothes that communicate, and garments that track vital signs, the team sees applications beyond clothing.

“It can be integrated with spacecraft skin to listen to (accumulating) space dust, or embedded into buildings to detect cracks or strains,” Dr. Yan said.

“It can even be woven into a smart net to monitor fish in the ocean. The fiber is opening widespread opportunities.”

“The learnings of this research offers quite literally a new way for fabrics to listen to our body and to the surrounding environment,” said Dr. Yoel Fink, also of MIT.

“The dedication of our students, postdocs and staff to advancing research which has always marveled me is especially relevant to this work, which was carried out during the pandemic.”

The team’s work appears in the journal Nature.

http://www.sci-news.com/othersciences/materials/acoustic-fabric-10631.html?utm_source=feedburner&utm_medium=email

Thanks to: http://www.sci-news.com

Mar 18, 2022 by News Staff / Sourc

Fabrics, by virtue of their composition and structure, have traditionally been used as acoustic absorbers. Inspired by the auditory system, a team of engineers from MIT and elsewhere has created a fabric that operates as a sensitive audible microphone while retaining the traditional qualities of fabrics, such as machine washability and draping.

Yan et al. designed an acoustic fabric, woven with a fiber that is designed from a piezoelectric material that produces an electrical signal when bent or mechanically deformed: (a) the tympanic membrane is a four-layer construct composed of circumferentially and radially oriented high-modulus collagen fibers, which are key for sound conduction; the tympanic membrane motion is ultimately transmitted to the cochlea through the ossicular chain, wherein short cilia fibers convert pressure waves into electrical signals (ionic), which are picked up by the nervous system; (b) in the acoustic fabric, high-modulus Twaron yarns and cotton yarns are oriented at right angles, mimicking the construction of the tympanic membrane; this construction converts faint audible frequency sound pressure waves into low-order mechanical vibration modes; within that same medium, a single strand of piezoelectric elastomeric fiber transducer is woven, leading to a synergistically coupled fabric, where sound transduction is a collective effect; this results in a fabric capable of operating as a sensitive microphone that detects weak sound signals (for example, human speech) as low as 10-7 atm. Image credit: Yan et al., doi: 10.1038/s41586-022-04476-9.

The ubiquity of fabrics, together with recent breakthroughs in fiber technology, enable us to challenge traditional uses of fabrics to encompass new and potentially useful roles.

Fabrics have recently been shown to store energy, communicate, heat, cool, display and even store and process digital information.

Motivated by the extent of fabric usage, its unparalleled proximity to the human body, and the importance of acoustic signals, MIT researcher Wei Yan and colleagues set out to investigate whether fabrics could serve as efficient sound collectors to detect and process even faint audible signals.

The consequences of such a transformation in fabric use would be far-reaching — enabling fabrics to mediate acoustic communications, pick up acoustic health indicators from the body, and increase situational acoustic awareness.

“We sought to create a fabric ‘ear’ that would be soft, durable, comfortable, and able to detect sound,” the scientists said.

“Our research led to two important discoveries: such a fabric would have to incorporate stiff, or high-modulus, fibers to effectively convert sound waves into vibrations.”

“And, we would have to design a fiber that could bend with the fabric and produce an electrical output in the process.”

“With these guidelines in mind, we developed a layered block of materials called a preform, made from a piezoelectric layer as well as ingredients to enhance the material’s vibrations in response to sound waves.”

“The resulting preform, about the size of a thick marker, was then heated and pulled like taffy into thin, 40-m- (131-foot) long fibers.”

The authors tested the fiber’s sensitivity to sound by attaching it to a suspended sheet of mylar.

They used a laser to measure the vibration of the sheet in response to sound played through a nearby speaker.

The sound varied in decibel between a quiet library and heavy road traffic. In response, the fiber vibrated and generated an electric current proportional to the sound played.

“This shows that the performance of the fiber on the membrane is comparable to a handheld microphone,” said Dr. Grace Noel, also from MIT.

The researchers wove the fiber with conventional yarns to produce panels of drapable, machine-washable fabric.

They then tested the fabric’s sensitivity to directional sound by clapping their hands while standing at various angles to the shirt.

“The fabric was able to detect the angle of the sound to within 1 degree at a distance of 3 m (10 feet) away,” Dr. Noel said.

The team also stitched a single fiber to a shirt’s inner lining, just over the chest region, and found it accurately detected the heartbeat of a healthy volunteer, along with subtle variations in the heart’s S1 and S2, or lub-dub features.

In addition to monitoring one’s own heartbeat, the authors see possibilities for incorporating the acoustic fabric into maternity wear to help monitor a baby’s fetal heartbeat.

Finally, they reversed the fiber’s function to serve not as a sound-detector but as a speaker.

They recorded a string of spoken words and fed the recording to the fiber in the form of an applied voltage.

The fiber converted the electrical signals to audible vibrations, which a second fiber was able to detect.

In addition to wearable hearing aids, clothes that communicate, and garments that track vital signs, the team sees applications beyond clothing.

“It can be integrated with spacecraft skin to listen to (accumulating) space dust, or embedded into buildings to detect cracks or strains,” Dr. Yan said.

“It can even be woven into a smart net to monitor fish in the ocean. The fiber is opening widespread opportunities.”

“The learnings of this research offers quite literally a new way for fabrics to listen to our body and to the surrounding environment,” said Dr. Yoel Fink, also of MIT.

“The dedication of our students, postdocs and staff to advancing research which has always marveled me is especially relevant to this work, which was carried out during the pandemic.”

The team’s work appears in the journal Nature.

http://www.sci-news.com/othersciences/materials/acoustic-fabric-10631.html?utm_source=feedburner&utm_medium=email

Thanks to: http://www.sci-news.com

Sat Mar 23, 2024 11:33 pm by globalturbo

Sat Mar 23, 2024 11:33 pm by globalturbo